The expansion joint and control joint two types of joints commonly used to accommodate movement and alleviate stress are paramount. As construction projects become more complex, the need for effective joint systems Understanding the distinction between expansion joints and control joints is crucial for architects, engineers, contractors, and building owners. By incorporating the appropriate joint system, they can ensure the longevity and durability of the structure. In this article, we will delve deeper into each type of joint, exploring their functions, applications, and best practices, helping you make informed decisions when it comes to your construction projects.

What Is A Control Joint

Control joint in construction is the systematic breaking point where cracking is allowed to occur to help control their location and formation for the contraction and expansion movement.

It theoretically ‘pre-designs’ the fracture; through the composite, the material must break in a controlled and constructive manner, rather than haphazardly, now we will show how expansion joint and control joint work.

It may be formed when placing the building material or it may be hacked after the material has been placed in the structure.

Haukke and Kropp have separately recommended that a saw-cut control joint in concrete can be made just at the surface of the concrete slab down to a depth of ½” (12mm) in order to create crack on purposely.

If the saw cut control joint was omitted, the concrete would crack in a haphazard manner specifically in the so called spider-cracking manner.

View the product Expansion Joint Solutions

Control Joint For PLASTER

Well-constructed control joints from iChem are important for the overall structural integrity of plasterwork where large areas such as ceilings and walls are concerned.

Holes in the structure are designed to help the plaster move to and from the direction of any force pushing it, caused by the change of, for instance, temperature, moisture, or building settling.

This will help to avoid cracks and gaps in the finished partitions, guaranteeing the decorative and practical qualities of the plastered surface.

Expansion Joints

Ichemeg Expansion joints are therefore parts of construction projects which work to allow for the expansion or contraction of constructional materials as a result of movement mainly due to temperature forces and other settling forces.

It helps avoid further damages and cracks in some structures and structural elements where parts of a construction are designed to be flexible to release stresses to maintain the solidity of structures, now you will learn how expansion joint and control joint work.

View the product Floor Expansion Joint Covers

How Expansion Joints Work

Movement Absorption: It refers to the spaces provided in the structural frame usually at certain intervals with the intention of preventing structures from moving together with floors, stairs and other structures.

Flexible Materials: Usually, they are made of soft or pliable materials including:

Neoprene: An incredibly tough and flexible synthetic rubber that goes by the name of Elastizell , specifically used in expansion joints.

Sealants: Elastomeric sealants that include silicone and polyurethane which enables waterproofing and also allows ability to move with the structure that is being sealed.

Pre-Formed Strips: Flexible assemblies of strips produced as a means of permitting movement in both a transverse and longitudinal nature.

View the product Control Joint

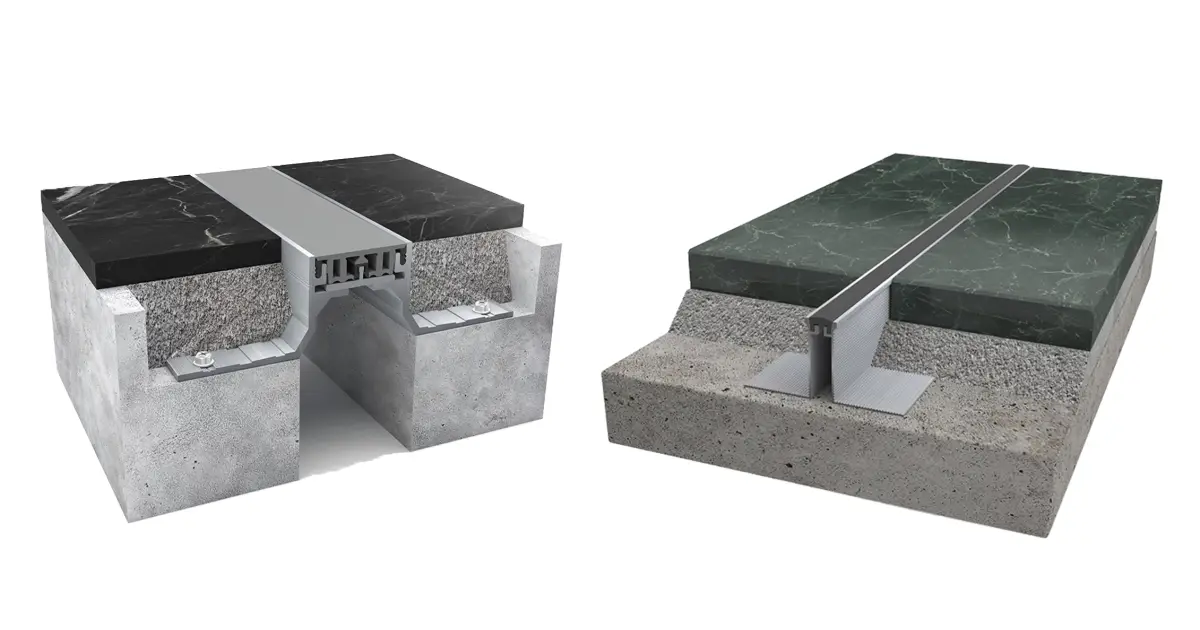

Expansion Joint Concrete

Ichemeg Movement joints or expansion joints are an important part of concreted structures to allow the building to move as a result of change in temperature and humidity as well as for structural movements.

It helps in averting crack formation and damage resultant from concrete construction due to the ability of independent movement of different parts of the concrete to ease stress and enhance the solidity of the concrete element when used in structures.

It is very important to ensure that you take your time and make sure that the concrete expansion joints are properly done because you can fix them before installing the concrete or even after.

In the first place, a thin and elastic material can be placed along the entire perimeter of the joining before the concrete is poured.

Alternatively, once the concrete has set grooves can be made on the concrete this will define where the concrete will crack and allow the joint to have neat saw cut at and, on the surface, joint material can also be added where necessary, but care must be taken to ensure the right depth is maintained.

Tips for placing concrete expansion joints

Interger joints should be placed approximately 30 times the thickness of the slab apart. Well, taking into consideration the different steps that have been mentioned above, for a slab which has a thickness of 100mm’s then the joints are supposed to be spaced at 3,000mm (3 meters).

Make sure joints are cut deep enough: They have to extend to at least one-quarter the thickness of the slab in which the software is to operate. The following are the recommended depths for cuts at different slab thickness: • For a 100mm slab, the joints should be cut to a depth of not less than 25mm.

When sawing seams thereafter the concrete has been poured to the site, don’t allow it to dry for too long. The joints of the concrete must be cut within 12 hours after finishing because if concrete joints are not cut on or before this time, concrete may crack.

Joints are most effective when the aspect ratio of the slab is kept to 1: For example, 5m x 5m if the slab is a narrower than it is long which is okay, this can be taken to a maximum of 1. For example, a room is 2m x 3m, never just wake up one morning and start placing concrete expansion joints randomly and if many are to be placed, consult a structural engineer.

View the product Wall & Ceiling Expansion Joint Covers

Expansion Joint Cover

iChem Expansion joint covers serve a dual purpose, they offer a clean and an appearance that is pleasing to the eyes in expansion joints when doing the expansion joint sealing while at the same time making sure that the functionality of the expansion joints is not altered in any way.

These covers are generally used with metal or plastic body and are especially created to blend into the surface of the floor or the wall.

In Expansion Joint and Control Joint What Is the Difference article we will show why expansion joint covers are important.

Control Joint Vs Expansion Joint Drywall

While both expansion joint and control joint serve important functions in construction, they differ in their purpose, design, and application.

1- expansion joint and control joint Purpose

Expansion joints are the major techniques that are used in making provisions for changes in the dimensions of construction due to fluctuations in temperatures.

It can be used to protect against electrostatic discharge, and its function is to protect against thermal stress.

On the other hand, control joints are used purposely to control the cracking of the structures to avoid extra pressure on the concrete slabs.

Their intended use is for controlling where cracks appear and inhibiting particularly uncontrollable cracking.

2- expansion joint and control joint Design

Expansion joints are generally implemented using flexible material to enable its movement while still acting as a sealant commonly, neoprene.

These are castellated uniformly to enable them to handle both the lateral and vertical movement of the structure.

However, the control joints can be gently made through cutting or tooling grooves on the concrete slabs.

They are specifically made to be less stiff than the rest of the concrete to purposefully control the places where cracking happens.

3- expansion joint and control joint Application

Expansion joints are frequently applied to extended facilities such as bridges, roads, and commercial structures, where thermal expansion and/or contraction are noticeable.

They are noble in the sense that they help to avoid the expansion or contraction consequences that are related to temperature differences in our buildings.

While the control joints are mainly used in some big projects such as dams, where the construction is fixed and the concrete is poured in sections, control joints are used in concrete slabs such as driveways or sidewalks, or in concrete floors.

Control joints will be localized to the plane of the treatment as in brick facades or concrete sidewalks; expansion joints, on the other hand, must pass through the building envelope and therefore running through the foundation, walls, curtain walls, plaza and parking deck slab and beams, floors and roof.

Thus, it is essential for the building to perform and meet the requirement of restoring the purpose and function of each building element through the use of purpose-designed expansion joints at the opening of the expansion joint.

control joint vs expansion joint masonry

while control joints in masonry are primarily used to manage minor, predictable cracking and maintain aesthetic control, expansion joints are employed to handle more significant structural movements and prevent major damage. expansion joint and control joint are essential for ensuring the durability and stability of masonry structures.

View the product Expansion Joint Solutions

construction joint vs control joint vs expansion joint

we show Purpose, Design and Application of expansion joint and control joint now we will talk about construction joint:

construction joint Purpose: Construction joints refer to those weaknesses or openings on a construction member that occur during construction process. They facilitate phased development, partial concrete placement, or linking of varying parts.

construction joint Design: It is mostly left empty and invariably serves the purpose of creating a divide.

construction joint Application: Construction joints are familiar in large concrete structures such as dams for the reason that it is impossible to pour the concrete in a single batch.

In Summary, Construction Joints is Breaks during construction, allowing for staged building but Control Joints is Control minor cracking caused by movement and Expansion Joints is Accommodate significant movement, preventing structural damage

What is the difference between expansion joint and building joint?

Expansion joints are needed in most construction projects; these are the areas where structures are designed to expand and contract when exposed to heat or cold.

These joints let large portions of a structure act like separate beams, constraining the formation of cracks and excessive movements which can harm structures due to thermal expansion.

Usually, these voids are in the form of rubber or foam and the common purpose of these expansion joints is to compress and expand when there is temperature variation so that the structural stresses are abated.

They are commonly employed in areas such bridges, roads, and big buildings; areas where temperature changes are pronounced and can otherwise cause lots of structural problems.

Construction joints or building joints are vital work breaks that involve creating joints that enable the construction of a structure in phases.

These joints dictate specific points where the concreting process is to stop and allow the next section to be cast to ensure that the individual sections when they are finally cast provide the required strength to the structure.

These are designed to allow small movements like shrinkage from drying of concrete or movement of foundations and are usually grouted to minimize leakage.

They also contain other mechanical interconnects to transfer loads across the joint. Used widely in civil engineering projects such as buildings and dams, building joints are used in projects wherein joining large concrete batches is either impotent or physically impossible.

What is the difference between an expansion joint and a contraction joint?

iChem Expansion joints and contraction joints are essential in construction for managing material movement but serve different purposes. Expansion joints accommodate the expansion of building materials due to temperature increases, allowing sections of a structure to move independently and prevent stress and cracking. They are filled with flexible materials like rubber or foam and are used in large structures such as bridges, roads, and buildings to absorb thermal expansion stress.

Contraction joints, on the other hand, control and manage cracks that occur due to the shrinkage of materials as they dry and cure. These joints create a weakened plane where the concrete can crack in a controlled manner, preventing random cracking. They are typically formed by tooling, saw cutting, or inserting pre-molded joint materials and are used in concrete slabs, pavements, walls, and floors to manage drying shrinkage and minor movements.

What is the difference between expansion joints and isolation joints?

iChem Expansion joints and isolation joints are essential in construction but have distinct purposes. Expansion joints accommodate material expansion due to temperature changes, preventing stress and damage by allowing independent movement. Commonly filled with flexible materials like rubber or foam, they are used in large structures exposed to temperature variations. In contrast, isolation joints separate different parts of a structure, preventing the transfer of loads or movements. Filled with compressible materials like cork or neoprene, isolation joints provide complete separation, crucial around columns, footings, and building perimeters to prevent structural issues caused by unexpected movements or pressures. In summary, both expansion joints and isolation joints ensure the safety and stability of the construction under various conditions.

What is the difference between expansion joint and control joint in EIFS?

In EIFS (Exterior Insulation and Finish Systems), expansion joint and control joint play distinct roles in managing movement and preventing damage. Expansion joints are integral for accommodating thermal expansion and contraction resulting from temperature changes. They allow EIFS panels or sections to move independently, reducing stress and potential structural damage. Typically filled with flexible materials like foam or elastomers, expansion joints are strategically placed along EIFS walls or between different sections of a building to absorb movement and maintain structural integrity.

Contact us :

On the other hand, control joints in EIFS serve to control and manage the occurrence of cracks within the system. By creating weakened planes in the EIFS material, control joints direct cracks along predetermined lines, preventing random and unsightly cracking. These joints can be formed through scoring, cutting, or by inserting pre-molded materials into the EIFS surface. Placed at regular intervals, control joints help to control cracking, particularly in large expanses of EIFS where movement and stress are more likely to occur.