iChem Control Joint Systems: The Complete Solution to Prevent Cracks in Concrete Floors & Slabs

Introduction

Control joints are essential components in any concrete slab or flooring system. They help control shrinkage cracks, manage thermal expansion and contraction, and ensure that any structural movement happens within a predefined joint—not in the middle of your concrete surface.

In the previous article, we explained what control joints are, why they matter, and how they work.

In this new guide, we focus on the next crucial step:

The advanced Control Joint Systems by iChem — engineered to protect floors, slabs, roofs, and building structures from cracking and thermal stress.

These systems are designed to meet Egyptian standards and international codes, offering long-lasting performance for industrial, commercial, and residential applications.

Why Control Joints Matter (and Why iChem Systems Lead the Market)

Installing iChem control joint systems ensures:

Precise crack control

Absorption of thermal and structural stresses

Smooth and natural movement between concrete slabs

Longer lifespan of floors and finishes

Protection against early failure in tiles, coatings, or concrete top layers

iChem systems are engineered for concrete slabs, slab-on-grade floors, industrial floors, roofs, façades, walls, and heavy-duty projects.

iChem Control Joint Systems (Full Product Guide)

Below is your complete guide to all iChem Control Joint Systems — functions, applications, and advantages.

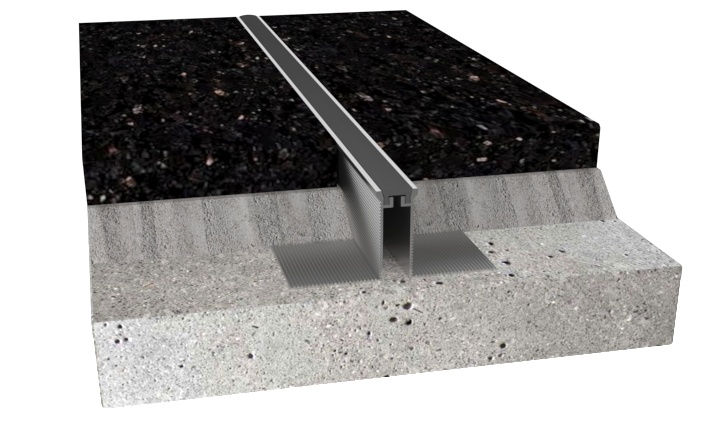

iChem i340: Structural Control Joint for Roofs & Exposed Concrete Surfaces

Technical Description

The iChem i340 system is a structural control joint designed to prevent unpredictable cracking caused by expansion and contraction.

It is installed in concrete roofs and slab-on-grade surfaces to ensure controlled movement and structural stability.

Key Features

Reduces unexpected surface cracking

Allows calculated expansion/contraction movement

Maintains clean and aesthetic joints

Suitable for areas exposed to temperature changes

Manufactured from high-quality, corrosion-resistant materials

Technical Specifications

Colors: Project-specific

Joint width: Designed per structural drawings

Frame height: Matches standard concrete thickness

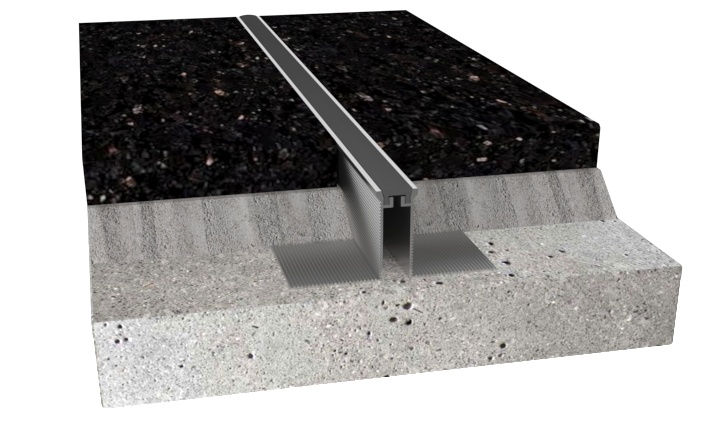

iChem i345: Aluminum Movement Joint for Floors & Tiles

Technical Description

The iChem i345 system is an aluminum movement joint designed to accommodate expansion between concrete floor slabs.

It provides excellent durability, smooth movement, and an aesthetically clean finish.

Key Features

Allows controlled horizontal and vertical movement

Ideal for industrial and commercial floors

High-strength aluminum profile

Suitable for concrete slabs, ceramic tiles, marble, and stone flooring

Best Applications

Shopping malls

Hospitals

Airports

Hotels

Warehouses & industrial floors

High-traffic commercial areas

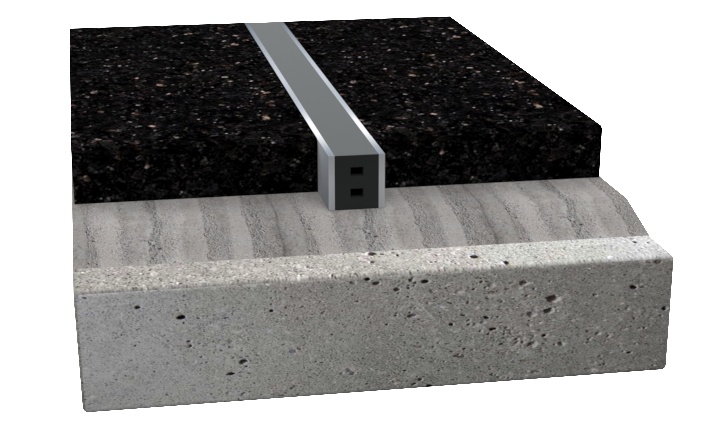

iChem i348: PVC Finishing Control Joint for Internal Floors

Technical Description

The iChem i348 PVC Joint is a flexible, chemical-resistant finishing joint designed to prevent cracks within floor finishing layers.

It is especially suitable for interior flooring where small thermal movements can cause finish failures.

Key Features

High flexibility

Moisture and chemical resistance

Ideal for light-to-medium load floors

Quick and easy installation

Perfect for indoor finishing layers

Why Choose iChem Control Joint Systems?

Competitive Advantages

Compliant with the Egyptian Code, EN standards, and ASTM

Manufactured with high-grade materials

Long service life & excellent weather resistance

Simple installation & low maintenance

Trusted by engineers, contractors, and consultants across Egypt

Technical support available for all project sizes

Quick Comparison: Control Joint vs. Expansion Joint

Feature | Control Joint | Expansion Joint |

|---|---|---|

Purpose | Controls shrinkage cracks | Allows large structural movement |

Size | Narrow joint | Wider, includes rubber or metal inserts |

Locations | Floors, slabs, finishes | Buildings, bridges, large structures |

Execution | During or after casting | During design and construction |

When Should You Install Control Joints?

After concrete placement (Saw-Cut Joints)

During casting (Preformed Joints)

Every 3–5 meters according to the Egyptian code

In areas exposed to temperature changes or high loads

How to Install Control Joints (Step-by-Step Guide)

Determine spacing based on code and slab thickness

Mark the joint layout before concrete placement

Install the suitable iChem system (i340 / i345 / i348)

Ensure straight alignment

Apply finishing and cleaning

Verify joint flexibility and movement clearance

FAQ: Control Joints & iChem Systems

What are control joints in concrete?

Control joints are intentional cuts or profiles that control where cracks will form due to shrinkage or thermal movement.

What is the difference between control joints and expansion joints?

Control joints manage small shrinkage cracks; expansion joints absorb large building movements.

Do control joints need sealant?

Saw-cut joints: sometimes require sealant

Preformed systems (i340 / i345 / i348): usually do NOT need sealant

What is the best control joint for industrial floors?

iChem i345 — heavy-duty aluminum joint designed for high-traffic floors.

What is the best joint for interior finishes?

iChem i348 — flexible PVC joint suitable for delicate indoor finishes.

What is the best joint for roofs?

iChem i340 — engineered to handle temperature variations and prevent unpredictable cracking.

How much do control joints cost in Egypt?

Cost depends on:

Joint type

Width & height

Quantity

Application (floors, roofs, tiles)

For exact pricing:

📞 01022000050

Need help choosing the right control joint system?

With iChem Control Joint Systems, you guarantee long-lasting protection, crack control, and superior concrete performance.

📞 Call Now: 01022000050

Our engineers will help you choose the perfect system for your project.